Fabric Based Laminates - Grade 2F/3/PTFE

Cotton fabric based laminate with added PTFE

Dry bearing laminate

Tufnol Grade 2F/3/PTFE is a unique, dry-bearing material. It is a cotton fabric reinforced laminate, internally lubricated by very fine particles of PTFE uniformly distributed throughout the material. This dispersion of the PTFE right throughout the material ensures that, whatever shape of component is machined from it, PTFE is always present at the bearing surface, modifying and improving the dry friction properties.

It is a laminated thermosetting resin material incorporating a fluoroplastics lubricant, and provides advantages derived from both materials, successfully combining the excellent mechanical strength, rigidity, toughness and good machining characteristics of phenolic laminates with the self-lubricating and low friction characteristics of PTFE.

- Cost-effective operation

- Reduced wear rate

- Minimizes maintenance

- Eliminates stick-slip motion and running-in periods

- Longer working life

- Easily machined

- Good mechanical strength and dimensional stability

As a thermoset material, Grade 2F/3/PTFE has several important advantages over thermoplastics, making it more widely acceptable for load bearing applications.

It has a cotton fabric base of medium weave, bonded with phenolic resin. During manufacture of the laminate a controlled percentage of ‘Fluon’® PTFE is built in. The mechanical strength of the PTFE lubricated laminate is significantly higher than that of thermoplastics bearing materials, as is its modulus of rigidity.

Grade 2F/3/PTFE can be used continuously at temperatures approaching 100°C and retains sufficient of its properties to be useful at temperatures approaching absolute zero. Under high stress, its creep and cold flow properties are superior to those of thermoplastics bearing materials.

Tufnol grade 2F/3/PTFE is resistant to dilute acids and bases but may be attacked by concentrated solutions. Its resistance to salts and common solvents is excellent, and its water absorption is low, with good dimensional stability under humid conditions.

All of these factors contribute to the versatility of TUFNOL Grade 2F/3/PTFE and make it one of the most useful dry-bearing materials available to engineers.

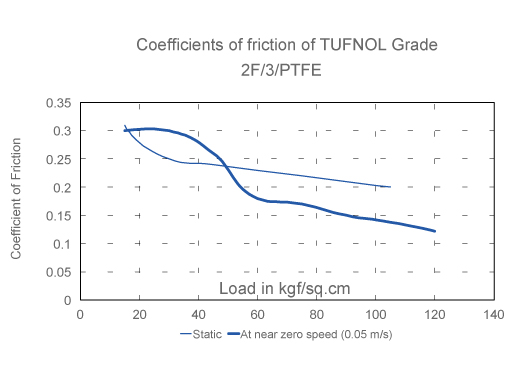

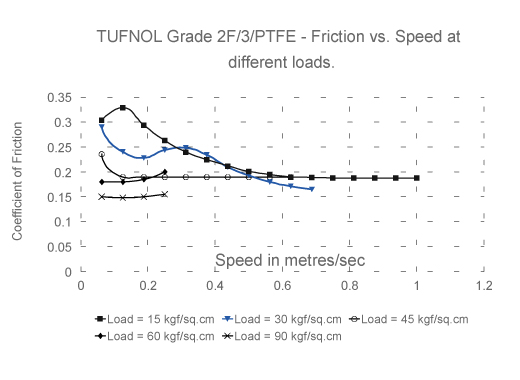

The frictional properties of Grade 2F/3/PTFE are quite outstanding in dry-bearing applications.

The mechanical strength of the base laminate combines with the frictional properties of the PTFE dispersion to give Grade 2F/3/PTFE a wear resistance which is many times greater than that of either of these materials individually. This allows it to be used with confidence at loads and speeds which would be considered prohibitive for many other dry-bearing materials. As shown in Figure 1, optimum balance of wear and performance is achieved at Pressure x Velocity (PV) values around 16.4* under loads of about 127 kgf/cm2 at 0.127 m/sec.

At somewhat lower speeds, say 0.04 to 0.05 m/sec the optimum PV value is about 10.7*. Grade 2F/3/PTFE has, in fact, survived very short term testing under loads exceeding 120 kgf/cm2 at PV values exceeding 36*. It will be appreciated that, although these loads are higher than normal for a dry-bearing material, they are quite realistic, since the material does not deform greatly under load.

![]() The PV values shown in Figure 1 represent the highest values which unlubricated specimens of TUFNOL Grade 2F/3/PTFE withstand in laboratory testing. The test specimen is a rectangular block with one face machined to provide a cylindrical bearing surface which is run against a 35 mm diameter hardened steel ring.

The PV values shown in Figure 1 represent the highest values which unlubricated specimens of TUFNOL Grade 2F/3/PTFE withstand in laboratory testing. The test specimen is a rectangular block with one face machined to provide a cylindrical bearing surface which is run against a 35 mm diameter hardened steel ring.

Dynamic coefficients of friction vary between 0.1 and 0.3 depending on load and speed, but tend to lie below 0.2 where high PV values are used. Coefficients of static friction are also low, helping to avoid ‘stick-slip’ movement at low sliding speeds.

glass fabric laminated standard size, glass fabric machining

It is commonly accepted that the results of bearing tests depend to some extent on the test method used and on the geometry of the specimen. Furthermore, manufacturers of materials may well have different criteria for judging whether or not a material’s performance is satisfactory at a given PV level.

For reasons such as these, the PV values indicated in Figure 1 be accepted as only an approximate guide to the performance of Tufnol Grade 2F/3/PTFE. In all cases, practical testing should be performed under full working conditions to assess the suitability of this material.

Tufnol Ltd will, of course, co-operate with engineers and designers wishing to arrange tests, and sample quantities of Tufnol Grade 2F/3/PTFE are available for experimental purposes. The Tufnol Technical Advisory Service is available to provide any further information which may be required.

*NOTE: All PV values are expressed in kgf/cm2 x m/sec.

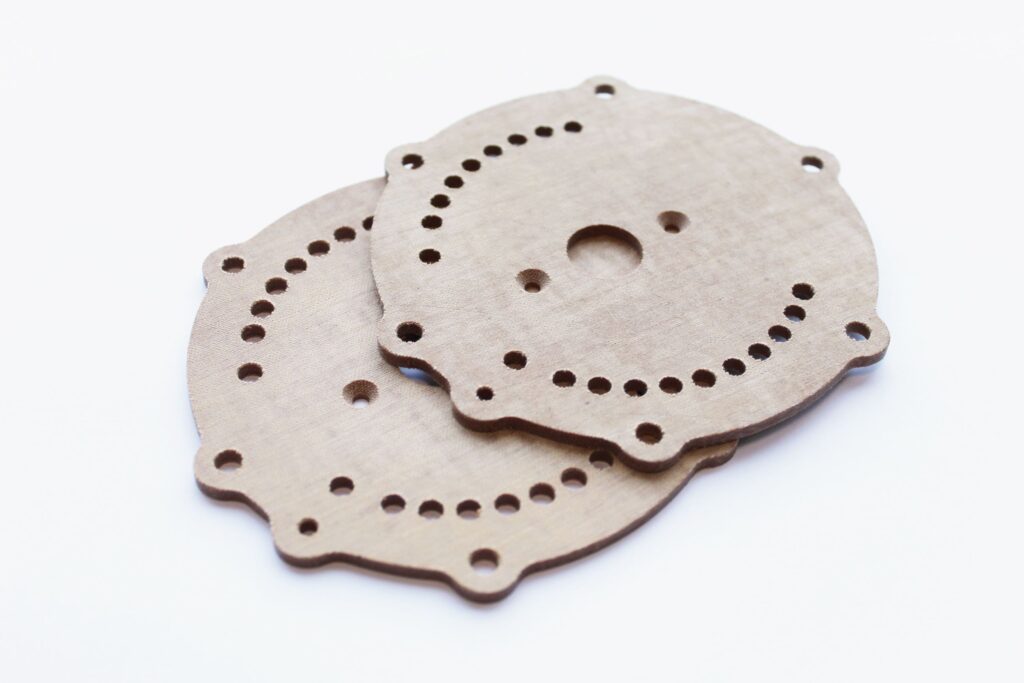

Components in a wide variety of shapes and sizes can easily be machined from Grade 2F/3/PTFE and the techniques used for machining it are similar to those for conventional laminated plastics. The uniform distribution of PTFE throughout the laminate ensures that whatever shape be machined, PTFE will be present at the bearing surface.

Application

- This high performance dry bearing material has many applications in the manufacturing industries where non-contaminating, silent running, long-life dry bearings are required.

Format

| Types Available | Sheets | Tubes |

|---|---|---|

| Natural colour | ✓ | ✓ |

View/Download Datasheet(s):

Standards

Tufnol Grade 2F/3/PTFE is a unique material and there are no British Standards or other national published specifications applicable to this type of material.

It is produced to the in-house quality specifications of Tufnol Composites Ltd.

Rod from Sheet: MS 8006 Issue 01