Designing Tufnol Laminated Gears

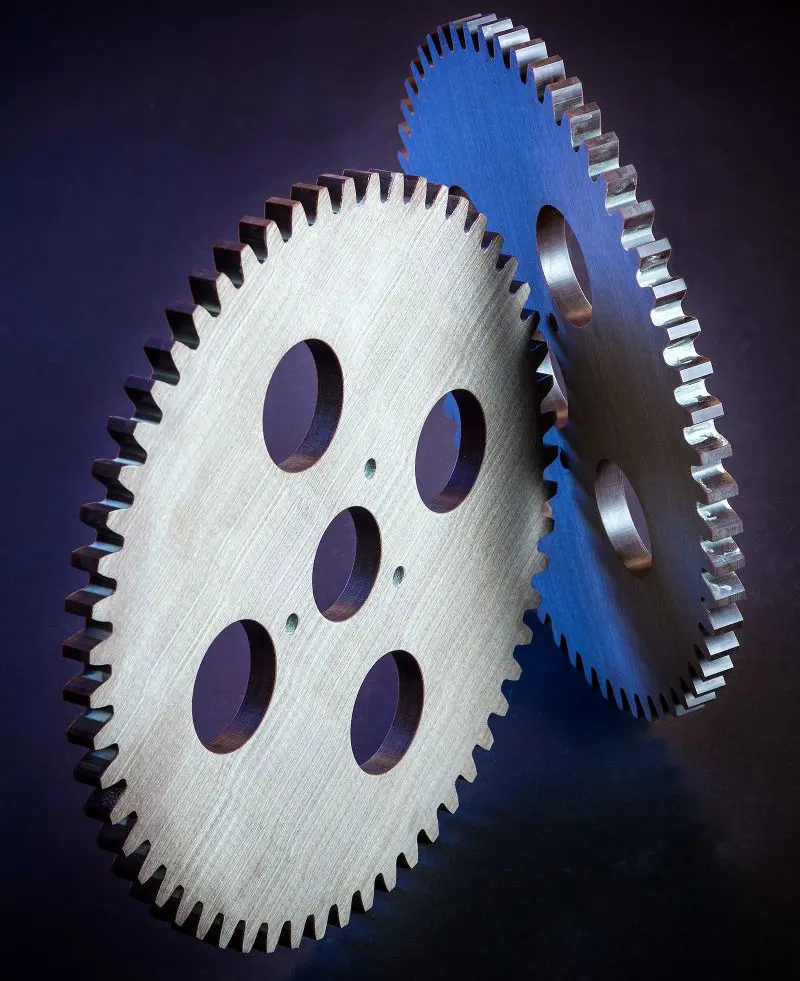

Tufnol materials are suitable for spur, single helical, double helical, bevel and internal gears.

They may also be used for some forms of spiral gears and racks. They should not, however, be used for worms but can be considered for worm wheels.

The pinion, or the wheel with the higher speed should normally be made from Tufnol laminates and the mating wheel from metal.

The metal gear should preferably be made of hardened steel but, failing this, a machine cut cast iron wheel usually gives good results. It should have machine-cut teeth because non-metallic gears will not mesh truly with a tooth having either a cast or machine-moulded finish.

Due to the comparatively low modulus of elasticity, the teeth of a Tufnol gear adapt themselves quickly to suit the profiles of the metal mating gear. Any slight inaccuracies in tooth form and spacing are soon accommodated.

Tufnol to Tufnol drives are not generally recommended as no additional benefits are achieved, except in a few special cases.

Such instances may occur, for example, in corrosive conditions or where electrical insulation is required.

Gear Design in Tufnol Laminates

Benefits

Non-metallic pinions machined from fabric reinforced Tufnol laminates are used successfully in many industries to reduce noise and to damp vibration in high speed machinery and equipment. This application extends from instruments to heavy-duty industrial plant.

Long life Tufnol laminated gears are hard wearing. They are also sympathetic to metals with which they work and this results in little or no wear on their mating wheels; often the life of the metal wheels is prolonged by the use of a Tufnol gear in the drive.

Tufnol laminates are unaffected by oil, grease or petrol, are generally suitable for use in corrosive atmospheres and can be stored indefinitely without deterioration.

Their mechanical strength, toughness, and temperature resistance exceed those of many commonly used thermoplastics materials and enable them to withstand extremely arduous working conditions, as well as the more delicate precision situations.

Their resilience provides good resistance to shock loads and their light weight – one sixth of the weight of steel – reduces inertia, which leads to lower power requirements.

Choice of Form and Grade

In order to obtain the maximum strength for a Tufnol spur gear, sheet material must be used so that the stress will be taken across the laminations.

Gears from Tufnol laminates can be made in diameters ranging from a few millimetres up to 1170mm (46in). Sheets can be made, in certain grades, up to 228mm (9in) thick but by riveting together two or more blanks, gears can be made with any width of face. This method can sometimes be more economical for gears less than 228mm (9in) face width. It is usual to machine gears from one of the cotton fabric based Tufnol brands according to tooth size and form.

As a general guide, Crow and Whale Brands are more suitable for coarse-pitched gears in rugged applications. Vole, Lynx and Carp Brands and Grade 6F/45 are mainly used when fine pitched gears are required. The finest weave materials, Carp Brand and Grade 6F/45, are especially suitable where an extremely fine finish is required or where the power throughput is slightly above that which the gear formula suggests the material will transmit. Grade 6F/45 is particularly distinguished for its superb, burr-free finish.

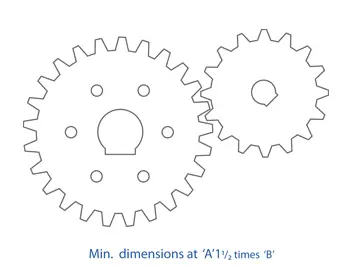

The face-width of a Tufnol gear should be a little less than that of the metal mating gear to ensure engagement over the full face width. The depth of material between the root of the tooth and the top of the keyway or rivets should not be less than one and a half times the tooth depth

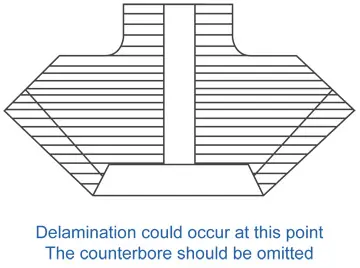

Counterbores and recesses should be omitted wherever possible. They do not contribute significantly to overall weight reduction and they do not assist in cost saving on material; indeed unnecessary extra machining may be involved. In some cases, such as certain bevel gears, recesses may cause undue weakening of the section

Tooth Form.

The generally accepted standard 200 pressure angle is normally used and is particularly advisable for gears with a small number of teeth, i.e., 18 or less, to avoid undercutting.

This results in weak teeth and leads to interference instead of required line contact on the path of action. For gears with a small number of teeth, it is preferable to increase the addendum and decrease the dedendum.

When required, a 14.1/2 degree angle can be utilised, but power capacity is reduced by up to 20%.

Recommended Pitch

The list of preferred pitches given in the table below are those which have been found to be most suited for TUFNOL gears. These may be varied, however, to suit particular conditions:

| Pitch | Power Capacity |

|---|

| Module | dp | kW | hp |

|---|---|---|---|

| 2.5 | 10 | 0.2 | 0.25 |

| 3 | 8 | 0.7 | 1 |

| 4 | 6 | 2 | 3 |

| 5 | 5 | 4 | 5 |

| 6 | 4 | 6 | 9 |

| 8 | 3 | 11 | 16 |

| 10 | 2.5 | 18 | 25 |

| 12 | 2 | 40 | 60 |

| 16 | 1.5 | 100 | 150 |

Lubrication

It is not essential to lubricate Tufnol gears. Like metal gears, however, their life is improved by the application of a good quality mineral oil.

Grease is not generally advisable except possibly in very clean situations, as it is liable to form an abrasive paste with embedded foreign matter.

Speeds. In general Tufnol laminates have greatest power capacity when operated at a pitch line velocity from 600 to 6000 feet per minute (3 to 30 metres per second).

Speeds above this may require special consideration but, at very low speeds, torque or tooth loading should be taken into account in assessing suitability.

Power Capacity

Side Plates

Metal side plates or “shrouds” are occasionally fitted, especially where the face width of the gear is fabricated from more than one piece of sheet. Also, where tapered keyways are used, they can help prevent excessive stress caused by the key being “overdriven”. In service, sturdy metal side plates can be beneficial for extremely arduous working conditions involving shock loading or severe abrasion.

Installation and Maintenance

Gears produced from Tufnol laminates will give a long and trouble-free life, provided certain points are borne in mind when fitting. The shafts should be checked for alignment and any play or wear in the bearings taken up. Shaft centre distances should be checked to give correct clearance and backlash. Care should also be taken to ensure that there is a minimum of end-play on the shafts, which might otherwise prevent correct engagement.

The pinion should be a good fit on the shaft and the key must engage the keyway for its entire length. The mating gear must run true and the teeth of the existing gears should be examined for signs of wear, incorrect tooth shape or general damage.